Xiamen Victory Aluminum Provides Professional Custom Aluminum Extrusion Profiles And Accessories,Aluminum OEM Service According To Your Special Requirements

الألمنيوم المخصص provides custom aluminum extrusion profiles and accessories,aluminum OEM&ODM&JDM customized service to our customers,we anticipate the needs of our clients by providing an integrated approach to maximize production efficiencies and a one-stop service in meeting our clients’ needs and requirements.

What You Can Get By Enjoying Our Custom Aluminum Extrusion Profiles And Accessories Service?

Although there are many companies that can provide custom aluminum extrusion profiles and accessories service,OEM service for metal manufacturing, when you choose to cooperate with Xiamen Victory Aluminum, the first thing you get is quality assurance, punctual delivery rate, and good after-sales service.

- Quality Assurance

The fully automatic machines mean that our custom aluminum extrusion profiles and accessories meet or exceed strict global industry standards.

- Punctual Delivery Rate

Our warehouse of more than 10,000 square meters guarantees that we can prepare inventory for you who place regular orders and guarantee the fastest delivery time to help you expand the market.

- Good Service

With more than 10 years of experience in the aluminum alloy industry and a professional support team ensure that our custom aluminum extrusion profiles and accessories meet your requirements, and even do better than you think.By cooperating with us, you will enjoy the best custom aluminum OEM service.

Based on the above reasons, you can get all the advantages of combining excellent quality aluminum products with precision engineering and reliable execution from our company.

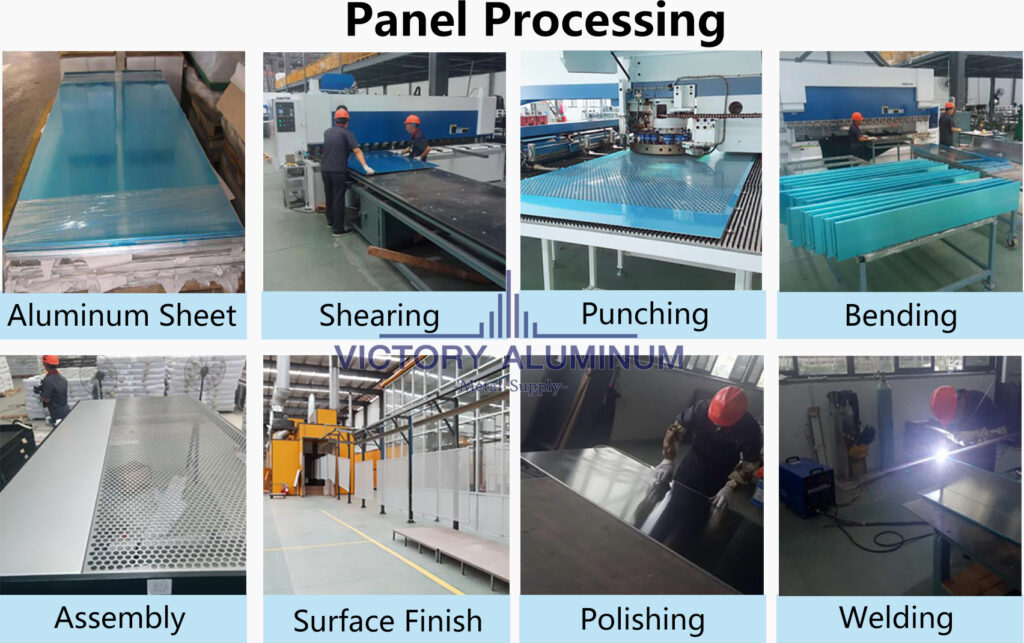

One-Stop Custom Aluminum OEM Service For Aluminum Profiles And Accessories Including Aluminum Extrusion •Fabrication •Painting •Anodize •Assembly •Precision Machining •Welding •Bending •Inventory •Engineering

الألمنيوم المخصص provides one-stop custom aluminum OEM service which includes manufacturing process such as aluminum extrusion,fabrication,تقوم شركتنا بتصميم وتصنيع قوالب بثق الألومنيوم لعمل عينات وفقًا للرسومات التي أكدها العملاء,anodize,assembly,precision machining, welding,الانحناء,inventory,engineering.This ensures the fastest service at the best quality to fulfill the aspirations of developers,تقوم شركتنا بتصميم وتصنيع قوالب بثق الألومنيوم لعمل عينات وفقًا للرسومات التي أكدها العملاء,تقوم شركتنا بتصميم وتصنيع قوالب بثق الألومنيوم لعمل عينات وفقًا للرسومات التي أكدها العملاء,designers and specialists’ contractors in their request to conceive building or projects which leaves lasting impression and popularity over the years.

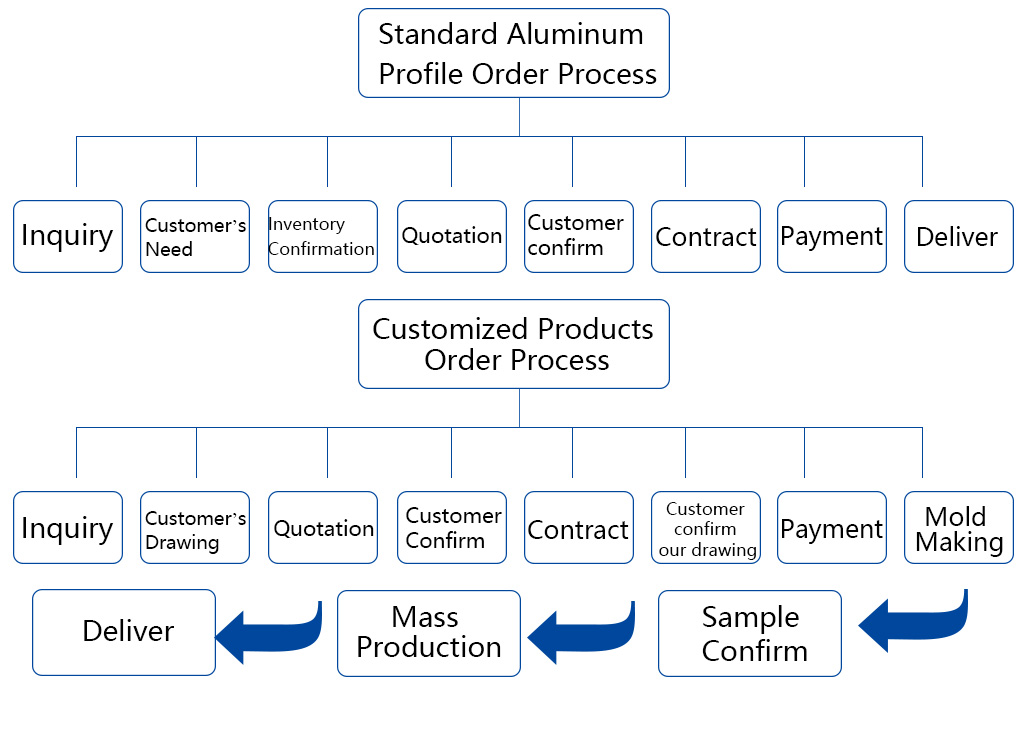

The following is the ordering process of standard aluminum alloy products and custom aluminum alloy products, please contact our sales staff for details.

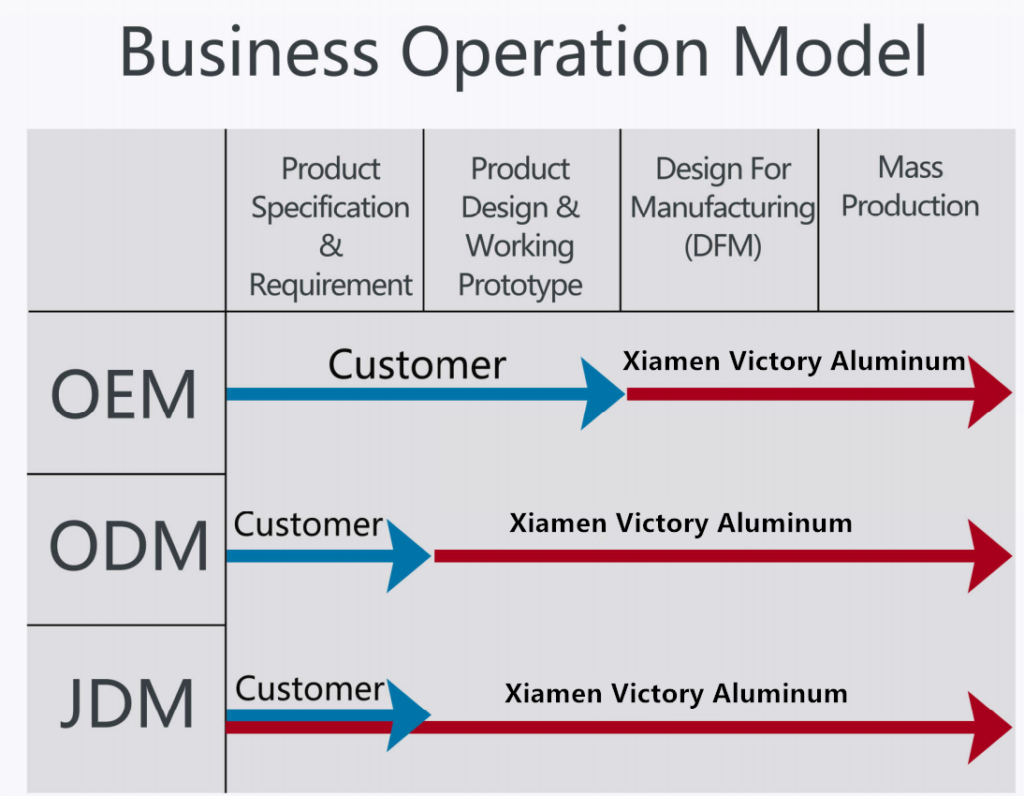

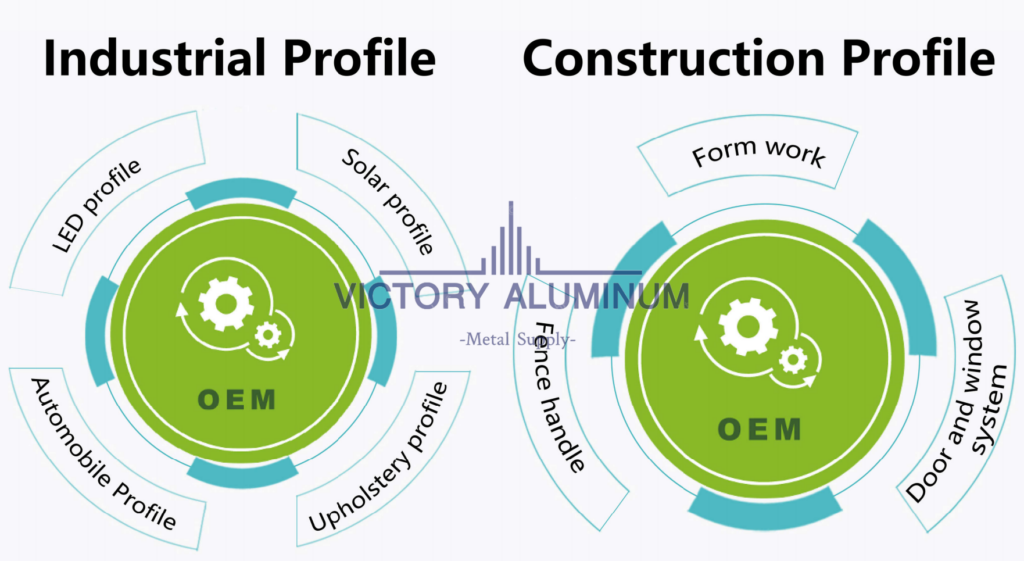

Business Operation Model

Our aluminum alloy production equipment is fully equipped and we have a professional support team. وبالتالي, we can provide various modes of cooperation.

Original Equipment Manufacturing(OEM)

- Customer owned design.

- Mass produce according to customer’s design.

Original Design Manufacturing(ODM)

- An extension of OEM.

- Design the products based on customer’s requirement and specification.

- Mass produce as according to the customer verified design.

- The product can be as simple as single part or a complex assembly.

Joint Development Manufacturing(JDM)

- A further extension of ODM.

- Develop the requirement and specification together with the customer.

- Design the product based on customer verified specification.

- Mass produce according to the customer verified design.

- The product can be as simple as a single part or a complex assembly.

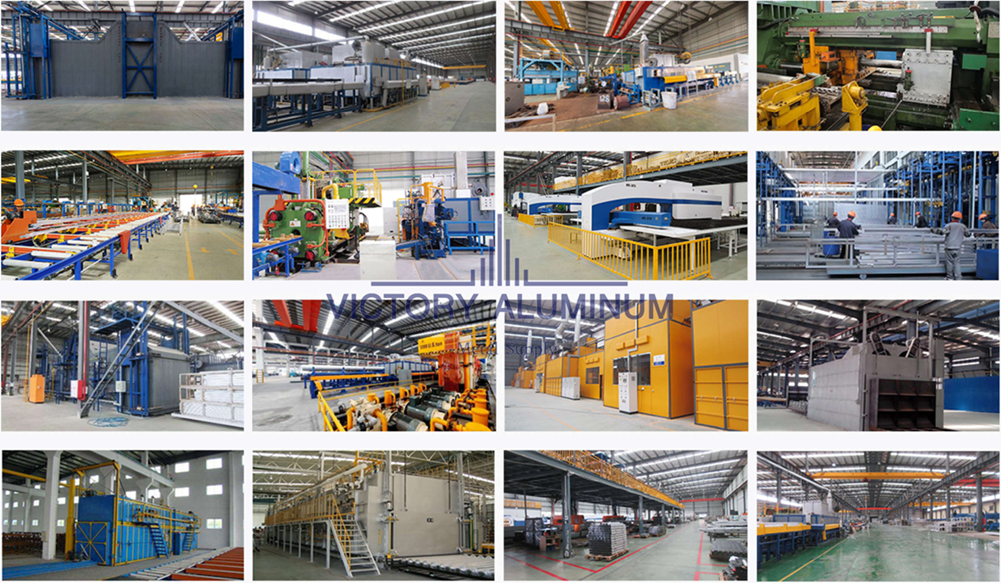

Manufacturing Equipments

We have melting and casting workshops, extrusion workshops, spraying workshops, oxidation anodizing workshops,precision machining workshops, deep processing workshops, sheet metal workshops, inventory warehouses, production scheduling center construction and factory areas.

The production equipments are made from Germany, Switzerland, South Korea, the production process is basically automated.

Custom Aluminum Capability

The factory covers an area of more than 150,000 متر مربع, and has an annual production capacity of 100,000 tons of high quality custom aluminum alloy profiles and accessories.

Based on this, we can provide customers with a large number of high-quality aluminum alloy extrusion profiles in a short time, and can provide customers with complete OEM aluminum service.

Process Flow

We have rich experience in the aluminum alloy product industry and can provide custom aluminum extrusion profiles and accessories of various grades, various hardness, and various surface treatments.

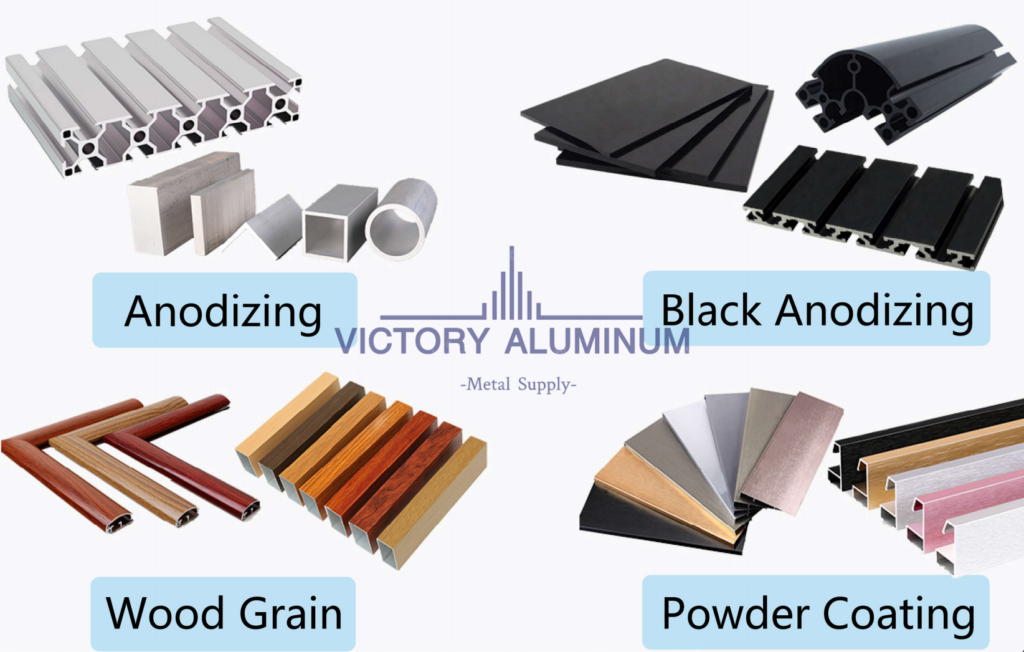

Surface Treatment For Aluminum Extrusion Products

The factory has a variety of complete production lines, which can achieve a variety of surface treatments.For Example,Anodizing, Sandblasting, Painting, Powder coating, Plating, Silk Printing, Brushing, Polishing, Laser Engraving,إلخ.

Our Value-added Customize Service

On the basis of complete equipment, professional team and years of industry experience, we can provide customers with a variety of deep processing services such as CNC Machining, Plastic Injection, Stamping, Die Casting, Silicone And Rubber, سحب الألمنيوم, Mould Making,إلخ.

Application

يغطي نطاق عملنا قطع غيار السيارات, آلات ومعدات, office and home furnishings,frameworks, communication equipment, electricity, electronics, and other industries.

في نفس الوقت,we also provide customers with customized and professional high-end aluminum extrusion profiles and finishing product.

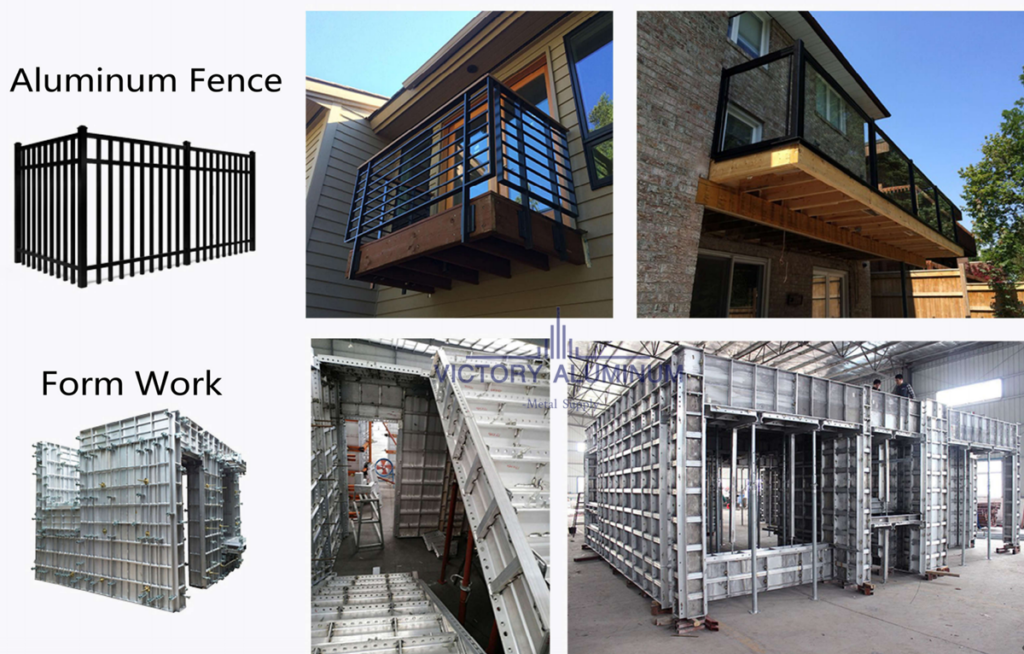

تتميز عبواتنا القياسية بحماية ممتازة للبضائع أثناء النقل,our main products are custom shaped aluminum profiles with open molds, industrial aluminum profiles, architectural aluminum profiles,aluminum alloy frames, building curtain wall profiles, heat-insulating aluminum profiles for doors and windows, and large cross-section radiator profiles, bars, plates, oversized round tubes, square tubes, and rectangular tubes,إلخ.

We not only provide industrial aluminum profiles, architectural aluminum profiles, aluminum alloy frames, architectural curtain wall profiles, doors and windows insulation aluminum profiles, but also large cross-section radiator profiles, bars, plates, oversized round tubes, square tubes, rectangular tubes, إلخ.

في نفس الوقت,we also provide customers with customized aluminum extrusion profiles and finishing product.

Why can we provide high quality custom aluminum alloy extrusion products with better price ?

الألمنيوم المخصص , as a manufacturer of customized extruded aluminum alloy profiles with many years of experience, has mastered a series of process methods to improve the quality of extruded aluminum profiles, so as to improve production efficiency, reduce costs and benefit customers.

-

Improving ingot quality is the premise to ensure extrusion quality.

Ingots are the raw material for extruded aluminum production. When the ingot has a uniform structure, fine grains, and no defects such as slag inclusion, pores, segregation, and cracks, it can not only reduce the extrusion force, increase the extrusion speed, and improve the intrinsic quality of the product, but also reduce the surface bubbles ,pores,cratches, الشقوق, pitting and other surface defects of the extruded aluminumproducts. We only choose high-quality AOO aluminum ingots to produce extruded custom aluminum profiles, it can ensure the yield and the quality of profiles from the source.

-

Properly increase the extrusion coefficient to ensure the quality of the extruded aluminum profiles.

Xiamen Victory Aluminum has a series of extruders of different models. During production, we will match the appropriate extruder according to the extrusion ratio of the product, the length of the cooling bed, the diameter of the circumcircle of the product, and the length and diameter of the extrusion barrel. When producing products of the same specification, because of the structure, performance and production efficiency of different extruders,and the output will also be different.In the extrusion production process, properly increasing the extrusion coefficient can not only obtain products with good mechanical properties and structure, but also improve the yield of extruded aluminum profiles and reduce production costs. The professional use of different extruders also ensures the first-class quality of Xiamen Victory Aluminum’s products.

-

Strengthen production management, accurately calculate the length of the ingot, and optimize the cost.

There are more and more applications of aluminum profiles in construction, transportation, electronics, tourism, and machinery. وبالتالي, the product variety of customized aluminum alloy profile factories is also increasing, which brings about the increase of molds and the arrangement of production plans difficulty. Before the production of Xiamen Victory Aluminum profiles, the professional team will calculate the number and length of the ingots according to the specifications, single weight, length, quantity and length of the cooling bed, so as to accurately cut out the suitable length of ingots to optimize the production cost of aluminum alloy products.

-

Use the clamping pad to reduce the length of the cutting head&tail to reduce the cost.

Most traditional manufacturers directly use jaws to clamp both ends of the flat profile, resulting in the deformation length of the two ends of the aluminum profile after stretching is often 0.4m ~ 1.2m or even longer,leading the lower rate of finished aluminum profiles. While Xiamen Victory Aluminum uses advanced clamping pads to reduce the amount of deformation along the section in the length direction.By this way,the cutting head and cutting tail of the profile can be much shorter to within 0.4m, the rate of finished products can increase to around 1.9%~3.8%, which greatly saves production materials and reduces costs.

-

Use the hot shear casting furnace to control the length of the ingot instantly.

Xiamen Victory Aluminum uses a hot shear long ingot heating furnace, which can avoid sawing of ingots and reduce the loss caused by aluminum chips. When extruding, the host hand can use the hot shearing ingot furnace according to the dynamic single weight of the mold. The shearing device can adjust the shearing length at any time to obtain aluminum ingots of any desired length, so that the cutting head and tail of the extruded long aluminum alloy profile can be shorter, and the rate of finished products can be higher. By using the hot shear casting rod furnace, the rate of finished products of aluminum alloy profiles of Xiamen Victory Aluminum can increase 2%~4%, which further reduces the production cost.

-

Strengthen the mold management and accurately record the dynamic single profile weight.

We accurately records the weight of a single aluminum profile extruded from each set of molds during the production process of aluminum alloy products, so as to improve the rate of finished products, cost accounting and mold management. We use computers for management, and acchive real-time data collection, workshop paperless, statistical automation, and information disclosure make the production process more standard, improve the rate of finished products and reduce costs.

-

Optimize extrusion process and reduce technical waste.

In addition to using the above measures to reduce geometric waste, it also minimizes technical waste in the production process. To be precise, it means that all products that should be genuine are genuine products, so as to avoid waste products. We have strict requirements on ingot quality, process temperature, extrusion speed, extrusion tools, molds, transfer loading and unloading, aging heat treatment, إلخ. In addition to formulating advanced and scientific production processes, we also insist on correct and strict implementation of process operating procedures,improve the technical proficiency and sense of responsibility of operators, so as to improve the qualification rate of aluminum alloy products and reduce costs.

If you have any needs of custom aluminum alloy profiles or OEM service requirement,please contact us at email:sales@vametalsupply.com

الدعم من قبل

الدعم من قبل